Reyburn & Bryant is a Northland survey firm that specialises in cadastral and subdivision work from Kaitaia in the north and as far south as Mangawhai to the south. Having kept a close eye on industry developments in aerial mapping technology, the company had been reluctant to invest in a Remotely Piloted Aircraft System (RPAS) as the cost was prohibitive for the amount of work it would generate. “Much of the Northland is covered by dense bush and scrub, whilst grassy areas are often left to grow naturally giving you little idea of the terrain underneath,” said Chris Knapp, a senior surveyor for the firm. “For that reason our use of RPAS technology is somewhat limited as for

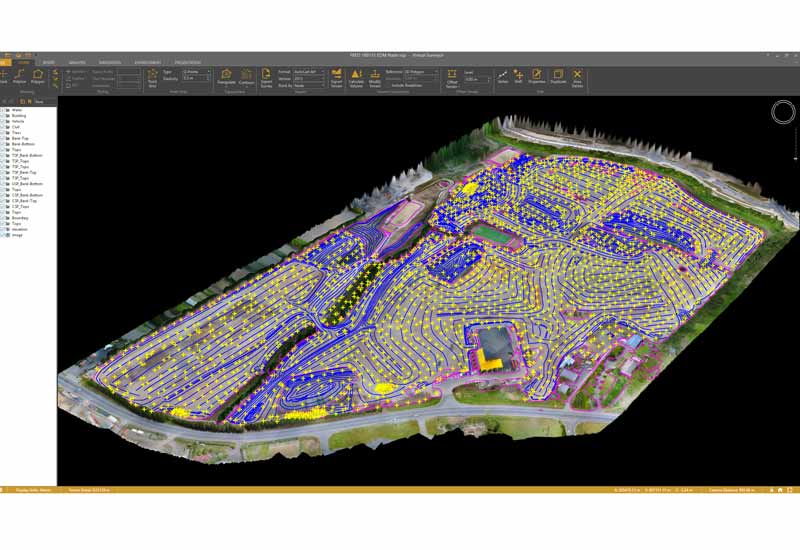

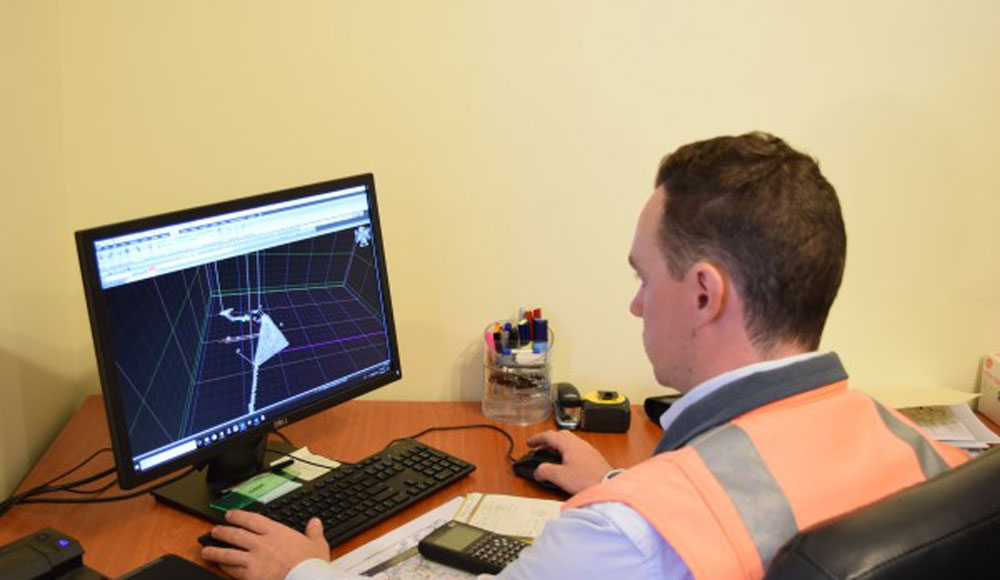

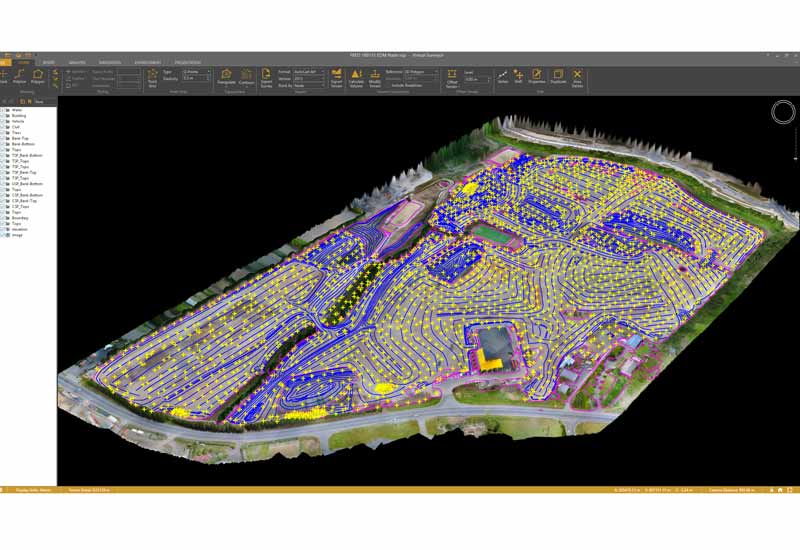

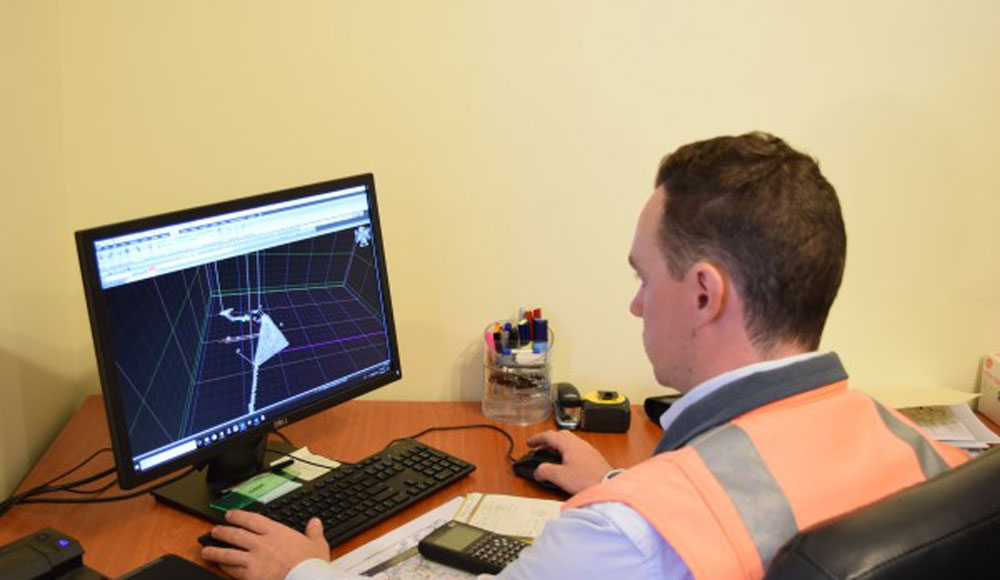

Bob Hick Earthmoving is a New Zealand construction company based in Silverdale, north of Auckland. Recently the firm invested in the latest Remotely Piloted Aircraft System (RPAS) technology to increase productivity and improve safety for its surveying teams on large projects. Survey Manager Chris Lübbe said the company did a great deal of research before settling on the DJI Phantom 4 Pro aircraft, complete with Propeller AeroPoints for ground control, along with Pix4D and Virtual Surveyor software for data analysis and visualisation tools. “We were looking for the best solution for the company in the long term, with the right balance of value for money and return on investment,” Mr Lübbe said. “We needed a stable and reliable

Auckland’s Ferry Building is an historic landmark in the New Zealand city. In the 100 years since it was built, the sea wall supporting the structure was gradually eroded by constant sea movement and wash from ferries docking and leaving the port. Divers discovered a large three-metre scour at the base of the sea wall that needed to be repaired and stabilised to ensure the safety and longevity of the building and underlying structure. After closer inspection a number of additional holes in the seawall were discovered. To ensure there was no damage to the building during repair works, Auckland Transport enlisted the services of CKL – a local engineering and surveying firm – to monitor the structure.

Collision awareness and proximity detection technology originally developed for the mining industry is set to become standard on major civil projects to protect workers and increase transparency for project managers. With limited space to manoeuvre and multiple heavy machines working in close proximity, roadside infrastructure projects can be a dangerous worksite. To reduce the risk of collisions between plant, people and utility or other fixed assets, geospatial positioning equipment distributor Aptella has introduced a range of proximity detection systems for civil construction applications by manufacturer Blue Electronics. Although collision awareness technology was initially developed to increase safety in mining applications, Blue Electronics’ solutions come with a enhanced features and failsafe measures to make them suitable for civil projects. Harry Katsanevas, Aptella

Sokkia introduces the latest addition to its iM line of manual total stations designed to provide powerful performance in an affordable package — the iM-50. “Whether operators need an instrument for jobs such as site layout or perhaps as-built survey, the iM-50 offers the perfect solution with high-end performance and exceptional functionality,” said Ray Kerwin, director of global surveying products. The iM-50 EDM features a prism range of up to 4,000 m and up to 500 m in reflectorless mode with a 1.5 mm/2 ppm accuracy. “The beam can precisely measure walls, corners, manholes on the road surface, even chain-link fences and tree branches. It offers a rapid distance measurement of 0.9 seconds regardless of the target,” he said. The instrument offers integrated

Andrew Blake, owner of Houlmann Blake Excavations, specialises in general construction works in Melbourne and is currently working on a typical basement excavation for an apartment block. Mr Blake has found that by implementing the iDig 2D machine control system from Aptella he has been able to avoid the regular challenges he encounters on site. “There’re no specific challenges we’re encountering on the site here, because we’re equipped with all the resources we need, and our team of operators also have all the latest technology available for them to carry out the works,” said Mr Blake. “We find the iDig system is working really well with the machines, the integration is seamless and we’re getting some great efficiencies out of our

PHL Surveyors has been using MAGNET software since the late 80s and first purchased a robotic total station, about seven years ago from Aptella. PHL Surveyors is involved in many facets of surveying, including, rural boundary definition, rural and urban sub-division as well as large scale irrigation design work, planning and engineering works. Alan Longhurst is one of three directors at PHL Surveyors and operates the Bungendore branch. “My role as a surveyor and planner is to take the projects in and distribute them to the staff. I do limited field work but I make sure that my staff is well equipped with the right technology and expertise,” said Mr Longhurst. “One of the projects we’re working on

If you want to improve the efficiency and safety of your landfill site, implementing a machine guidance system, such as Aptella’ Carlson LandfillGrade, is one of the most productive ways to achieve this goal. “The Carlson LandfillGrade machine guidance system helps our customers improve the efficiency and safety of their landfill sites through the maximisation of vertical space, leachate management, avoidance zones for gas wells and hazardous material placement and access to better, more accurate data,” said Andrew Granger, National Manager – Mining, Solar and Landfill at Aptella. To assist landfill site operators to achieve their goals, the Carlson LandfillGrade machine guidance system will assist in optimising the amount of soil used for daily cover (along with the introduction of an alternate