Adding grade control to your excavator comes with a host of benefits. It saves time by getting you to grade faster, reduces or eliminates overcutting and re-work, and can cut labour costs by negating the need for a grade checker. However, for many contractors, justifying the cost when margins are tight enough as it is can be a challenge. iDig is a lower-cost, versatile grade checking system that can be fitted to any make, model or size of excavator and work with multiple buckets, including tilt buckets and augers. There are also options for non-centre pivot machines. “This system is a game changer for contractors that want the benefits of grade control on their excavator, but can’t justify

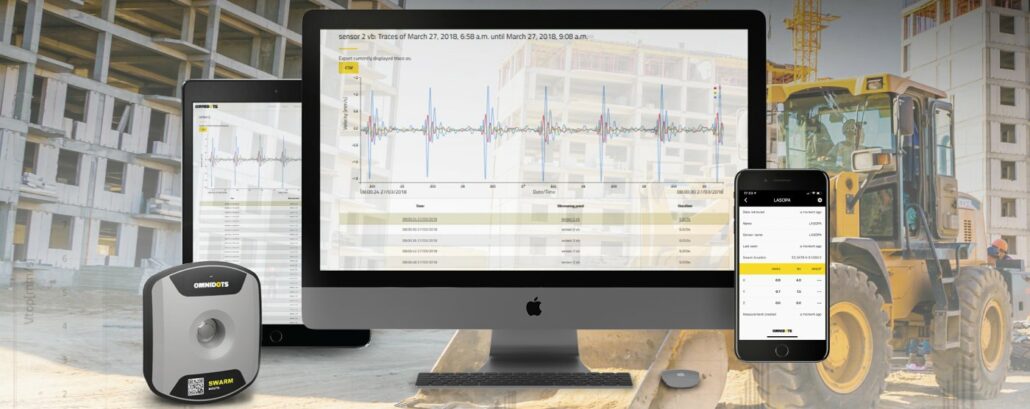

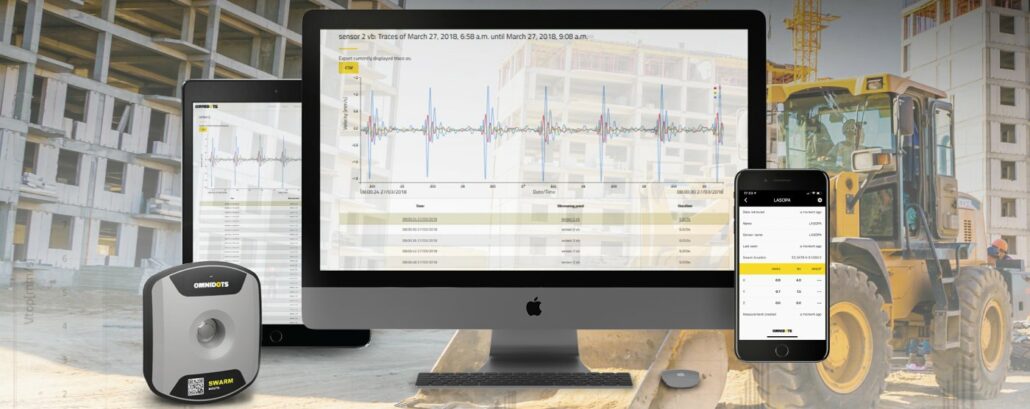

Intelligent positioning solutions provider Aptella to distribute Omnidots’ innovative wireless vibration monitoring platform throughout Australia and New Zealand. Omnidots specialises in easy to setup, autonomous, reliable vibration monitoring systems for use in infrastructure and geophysical applications. Under the agreement, Aptella has been appointed Master Distributor for the Omnidots range. “The Omnidots solution is unique in its capacity to deliver a fully automated, wireless, and integrated vibration monitoring platform that can be installed and setup in minutes,” said Andrew Jones, Monitoring Marketing Development Manager at Aptella. “The Omnidots range compliments our other deformation monitoring solutions and has already received very positive feedback from customers using it for commercial construction and infrastructure projects,” he added. Vibration monitoring is important in

FREE online training and certification with a 12-month Pix4Dmapper subscription! Save NZ $600 Hurry, this offer must end on 30th June 2021 Free training and certification Pix4Dmapper is your must-have photogrammetry software for survey drone data, transforming imagery into digital maps and 3D models for you to analyse, measure and control. Capture: RGB, thermal or multispectral images with any camera Ditigise: Process your survey drone data into digital maps or 3D models Control: Unique rayCloud environment helps you check and control the quality of your data Measure & Inspect: Quickly and accurately measure distances, areas and volumes in a digital environment Collaborate & share: Safely and securely share projects with key More Info Webinar – Overcoming the Challenges

Experts in laser level calibrations! Book your clean and calibration today! Book In Your Laser Level Calibration Service With Our Team Of Experienced Technicians. Visit our service centre in Auckland or book online. Book Online Aptella services all brands and models of laser levels, digital levels and auto levels used in the construction industry. Enquire Now Aptella has service centres in all states and territories of Australia including Sydney, Brisbane, Melbourne, Adelaide, Perth, Canberra, Darwin and Tasmania. With manufacturer trained technicians that can clean, calibrate, repair and service all makes and models of laser levels and construction levels as well as Topcon and Sokkia optical and machine systems technology. If you’re looking to repair or service your laser

Market leading Australian company, experiencing strong growth Great team environment Attractive package, including desirable benefits Aptella is Australia’s premier provider of positioning and machine control solutions for surveying, civil works and building activities. As a premium precision technology company, Aptella offers an exciting and diverse range of career opportunities. Our people are innovative, passionate and energetic – working as one team with one high-performance culture. As part of our plan for continued growth, we now have an exciting opportunity for a Business Development Manager for Deformation Monitoring to join our team at our New Zealand office, based in Auckland. We support our clients i.e. surveyors, engineers and monitoring companies to protect and maintain their assets and infrastructure across

Did You Miss Our Webinar? Don’t Worry, You Can watch Our On-Demand Webinar In this webinar, you’ll learn how Pix4D’s new geospatial solutions – Pix4Dmapper, Pix4Dmatic and Pix4Dsurvey – can help to optimise the surveying and mapping workflows to achieve accurate results and get the relevant information your team needs. Key topics: – Photogrammetry pipeline: processing your data into accurate point clouds, digital surface models (DSM) and orthomosaic – Creation of engineering-ready CAD files from photogrammetry projects – Different user cases – Q&A session Acess On-Demand Webinar Limited Time Offer – Free training and certification FREE Online Training And Certification With A 12-Month Pix4Dmapper Subscription! SAVE NZ $600 Request More Info

The National Measurement Institute (NMI) advises that industrial scales should be calibrated every 6-12 months depending on the stresses applied to the scale, or after major hydraulic work is completed on the scale. This is for maintaining accuracy, fairness, and to comply with regulations that could otherwise cost you. Maintaining accuracy No matter how robust your industrial scale is, over time it becomes less accurate from natural wear-and-tear. Maintaining accuracy is important for both trade and non-trade purposes, including adhering to the load bearing capacity of a machine, or ensuring you have enough of a certain material for a construction project. When measuring large quantities of material, even a small discrepancy in the scale’s accuracy can result in

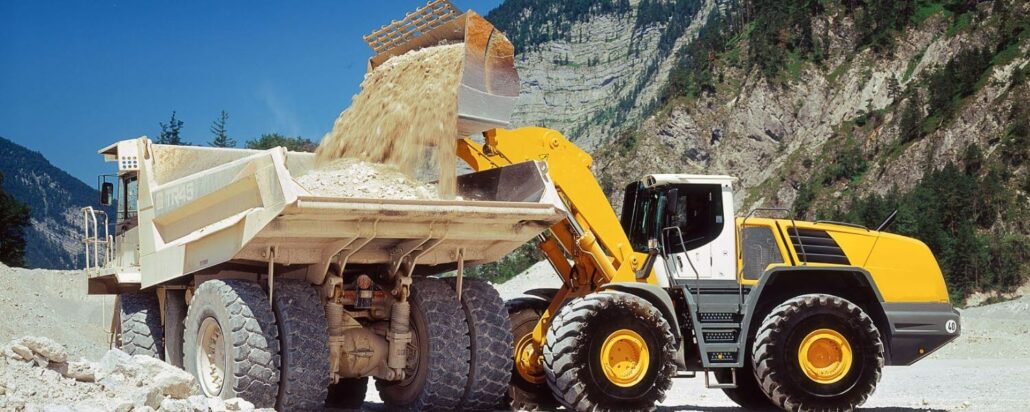

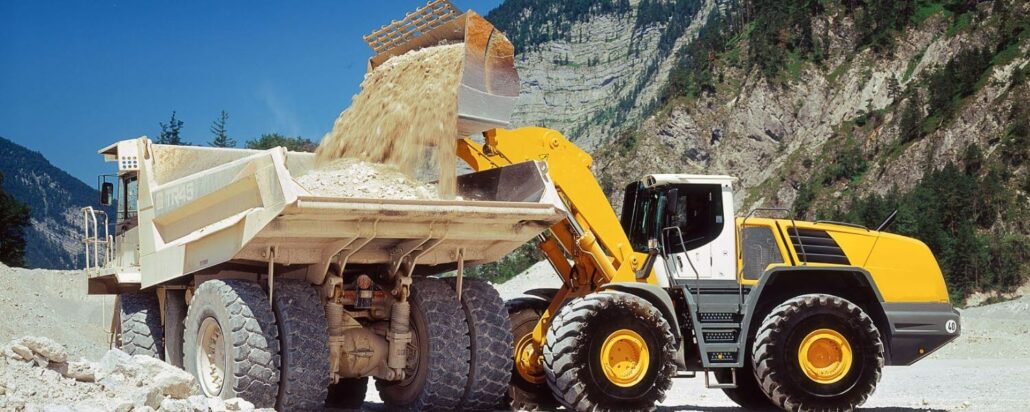

Machine operators, port workers, garden centre managers, and anyone who works with a loose material should be aware of the types of scales available to them, which are suitable for their needs, and what their requirements are. Learn more about the types of scales and which you should upgrade to below. Front end loader scales Front end loader scales are weighing systems built into the loaders’ hydraulic lift lines and feature an easy-to-read visual display. With front end loader scales, operators can determine the weight of the load simply by lifting the bucket at a constant lift speed, rather than having to drive to the weighbridge, stop, and turn around if loaded incorrectly. Weighing loads on front end