Andrew Granger is the business manager for mining, solar and landfill solutions at Aptella. Here, he outlines the key benefits to implementing GPS machine guidance on landfill sites. As the population grows, so too does the demand for waste management facilities. The pressure is on our industry to ensure landfill management is as efficient and productive as possible, maximising every potential to save on space, time, and resources. Accurate and optimised compaction is critical to delivering on these goals. Are you using GPS to manage your compaction? Poor compaction exposes a landfill site to numerous risks, including inefficient airspace use, greater settlement, and shortened cell life, all leading to lost time and money. Relying solely on an operator’s

Introducing construction set out Have you ever tasked your skilled tradesmen with hours of set out, painstakingly using a string line and tape measures? Or forked out hundreds in labour costs, only to discover your work was out by a few critical millimetres? Suffered extra project time re-doing your work, or trying to organise a surveyor to come to site? You are not alone. An estimated 90% of construction sites Australia-wide are still using string lines and a tape measure for set out. This leads to measurement mistakes, which leads to project delays and an increase in project costs to fix these mistakes. Surely there’s an easier way. That’s why Aptella is offering a hassle-free, easy, construction set

July 2021 has seen the NSW government shut down all construction works across the Sydney, Central Coast, Blue Mountains and Wollongong areas. Amongst organising site-security and shut down, head contactors and the sub-contractors that were mobilised onsite are now in planning mode. What will the re-opening of construction sites look like? When will this occur and in what capacity? How will we re-mobilise, get back to the works that were halted, and most importantly how will we be able to get back on-time and on-schedule. One of the considerations will be ‘do we need to create a new schedule for the build or try to catch up on lost time and meet the previous contracted schedule?’ The Topcon

Lauren Baguley, Surveyor, Fyfe was looking for an alternative to UHF when working in the highly vegetated and hilly regions, particularly in the Pilliga Forest near Narrabri, when she was introduced to MiRTK internet enabled corrections from Aptella by a colleague. Ms Baguley and her team focuses on surveying and aerial mapping within the agricultural, construction and mining industries for the Narrabri area. “We do struggle with UHF when we’re out in the scrubby country around here, it’s quite hilly. Where there’s a lot of vegetation, sometimes we can’t even get a kilometre away from the base so there’s a lot of leap frogging going on and having to set up the base multiple times is painful when

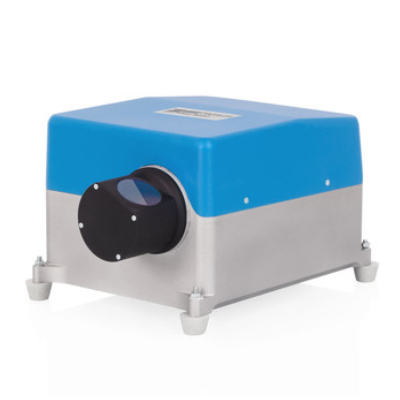

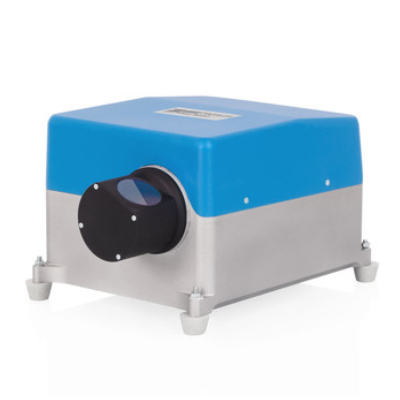

This highly efficient 2D laser scanner is made for mobile mapping applications and with its scan rate of more than 1 million points/sec. and scanning speed up to 267 profiles/sec., very short distances between profiles can be achieved even at a high speed of a moving platform. The PROFILER 9020 offers significant accuracy and speed improvements over the previous generation 9012, in a form factor that is 50% smaller and lighter,” said Geoffrey Preece, Market Development Manager – Scanning, Aptella. The PROFILER features a new and very powerful laser technology as well as further developed algorithms that ensures highly accurate measurement results on rails, roads, street signs and other traffic control systems, such as traffic lights. “The PROFILER

Building Commissioner David Chandler has announced two new Acts in New South Wales that aim to combat poor build quality in some multi-story housing developments. At the same time Mr Chandler has been granted significantly increased rights and powers when it comes to shutting down work sites, through stop-work-orders for poor builds and as of July 1st 2021, for poor reporting and record keeping. The new Acts mean that all designs must be submitted and approved ‘for construction’ and uploaded into the portal six months before work on site begins. The builder will then need to build to this design and any changes to be re-submitted. The Topcon LN-150 construction set out tool from Aptella makes this process

The Topcon LS-B100 machine-mounted laser receiver from Aptella offers accelerated accuracy for grading and excavating, improves safety on site and increases profitability. The LS-B100 machine mounted laser receiver is an affordable grade indicate system designed to improve grading and excavating production and accuracy. Other features include: Fast set-up and easy-to-use, the LS-B100 receiver can be mounted to your machine in minutes 360º laser detection Large working range Indicate control Rugged, waterproof design On-grade matching Universal pole clamp Increase accuracy Attach the LS-B100 to your dozer, scraper, excavator, backhoe or drag-boxes, turn it on, bench in and go to work. No more waiting for a grade checker or jumping off your machine to check your own grade. With the

ACI Excavations has a reputation for being early adopters of cutting-edge technology, and so it was no surprise that when the company purchased its latest piece of machinery, a 220x series excavator from JCB CEA, they paired it with Topcon’s new X-53x auto excavator system from Aptella. “We go back a long way with Topcon technology, lasers and integrated systems with rotating lasers,” said Peter Stadelbauer, Owner, ACI Excavations. “You have to be one step ahead of the opposition, if you’re not, you run last.” Why did ACI Excavations choose technology from Aptella? ACI Excavations has a long-standing relationship with Aptella and Topcon technology that goes back more than 30 years When the Topcon X-53x auto excavator was