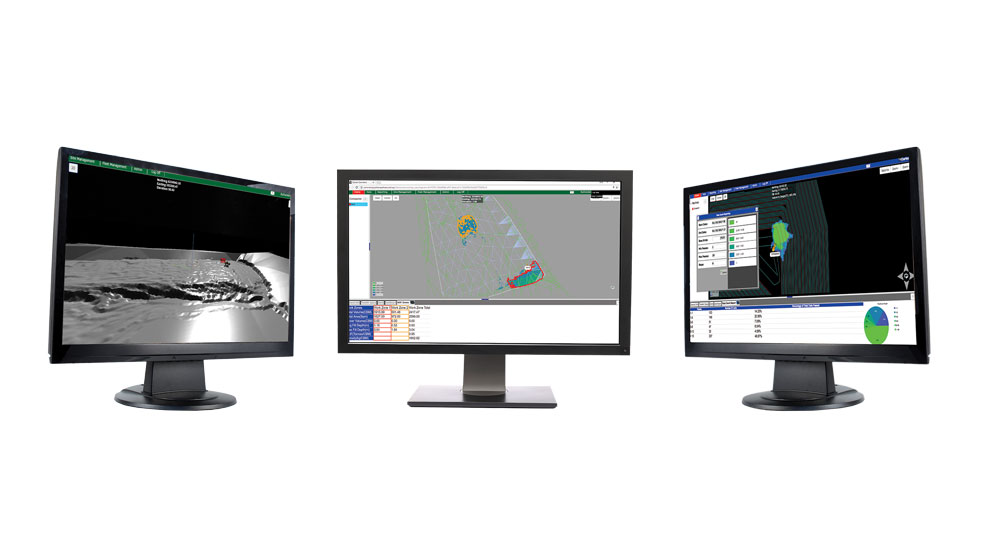

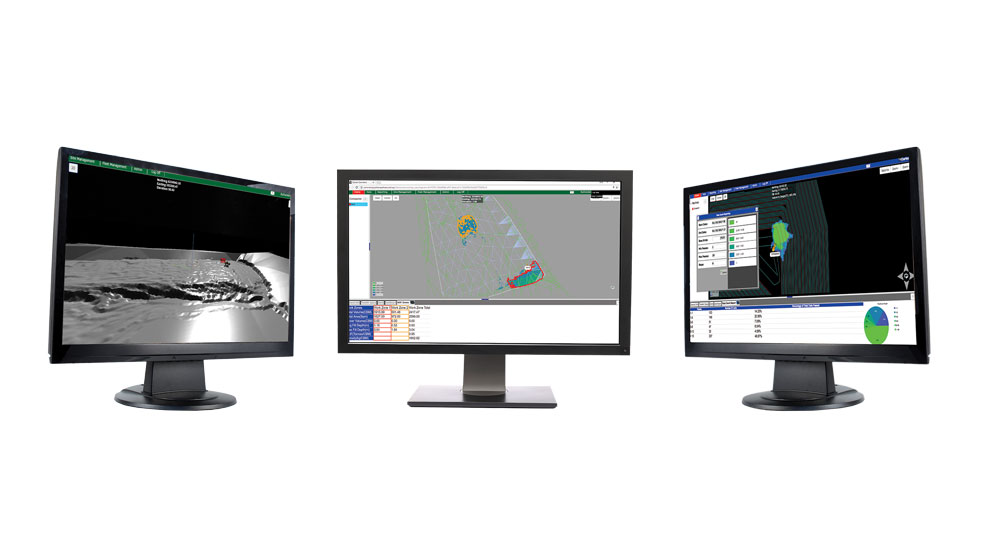

Aptella recently signed a contract with Carlson machine guidance, enabling Aptella to offer Carlson machine guidance and fleet management solutions for the mining, quarrying, dredging and landfill operations in South East Asia. “We are delighted to be able to offer our customers this complete range of machine guidance options,” said Martin Nix, Managing Director at Aptella. “Carlson has an open system architecture which enables the products to work on most makes and models of mine equipment,” he added. “We look forward to working with Carlson Machine Control to deliver the right combination of solutions to help increase productivity, improve safety and machine utilisation,” said Martin. “Aptella has been an exclusive Carlson Machine Control distributor since 2013 for Australia

Aptella has announced it is expanding into South East Asia, with the opening of a new branch in Indonesia. This latest move sees the Australian-owned positioning and machine control solutions company building upon its recent expansion into New Zealand, to meet the increased demand for its services outside Australia. Aptella managing director Martin Nix said there was increasing demand in the region for new technologies. “By opening an office in South East Asia we will be able to offer a range of solutions for the mining, engineering and construction industries,” he said. Mr Nix said Aptella’ South East Asia would offer sales and hire services across a range of positioning technologies, including Topcon Machine Control for civil construction,

Cohen & Associates is a Tasmanian survey company with a core business of land surveying, including cadastral and engineering projects. Recently, the company has invested in state-of-the-art Unmanned Aerial System (UAS) technology and is pushing the boundaries in near-infrared and aerial mapping for the agriculture industry. Adrian Fairfield is a Director of the company and a registered land surveyor. He explains that his team’s prior experience with remote sensing applications using satellite-based and manned aircraft led them to explore the possibilities of saving time and increasing efficiency with an unmanned solution. “Over the years, we’ve developed unique processes for remote sensing applications using satellite-based and manned aircraft,” he said. “These had their limitations, however, as you needed to

Jared Reeves has worked as a Surveyor for more than 10 years. When Unmanned Aerial System (UAS) technology came across his radar, he saw the huge potential to save time, improve data quality and increase efficiency for a wide range of surveying tasks in numerous industries. “Having spent many years working in the field collecting data manually using GPS, I understood the impact UAS technology could have on the surveying industry from an efficiency perspective,” Mr Reeves explained. “I also think that many survey firms will find it hard to justify the costs of investing in a drone themselves, so I saw the opportunity to start my own aerial survey contracting business to provide specialist services,” he added.

Every year, a group of University of Queensland mining engineering students gets have the opportunity to work with the latest mine surveying technology through a unique arrangement with positioning systems and machine control supplier Aptella. For the past three years, Aptella has hosted a practical field survey course for University of Queensland (UQ) second year mining engineering students at the former Wattle Glen Extended open cut mine near Ipswich in western Brisbane. As part of their degrees, UQ mining engineering students are required to complete a module on mine site surveying, designed to give them a basic understanding of surveying practice and technology. Up to 100 students participate in the field course, gaining hands-on experience with technology including